Our Gold

STEP 1

Our metal suppliers purchase pre-loved gold in the form of unwanted jewellery and jewellery processing elements. This 100% recycled precious metal is then refined to make mill products such as casting grain.

STEP 2

Our suppliers are SCS (Scientific Certification Systems) Certified, meaning they hold the credentials for the responsible sourcing of precious metals. This certification doesn't just cover the use of recycled metals, but it governs a range of business practices related to sustainability and ethical working conditions too.

STEP 3

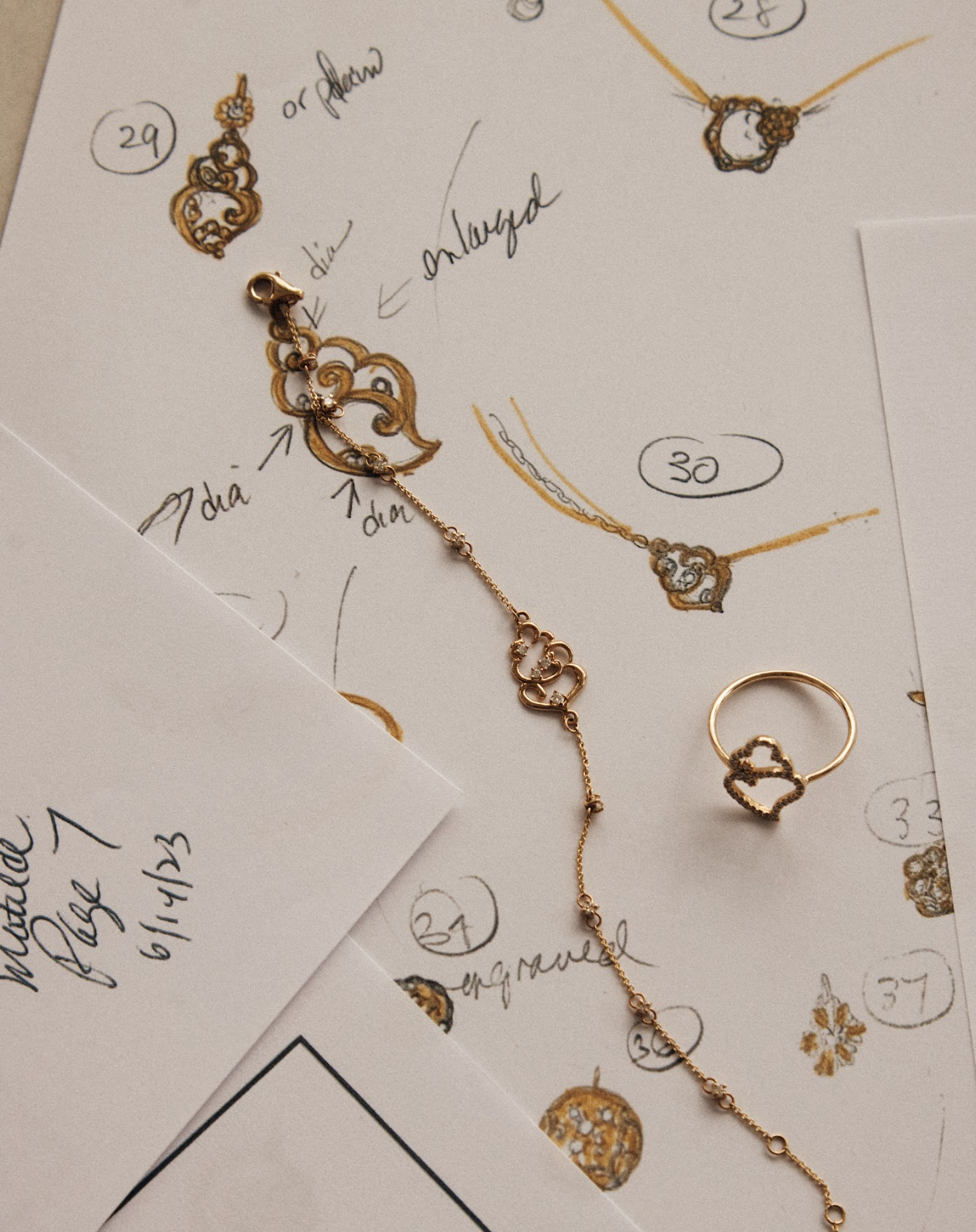

Jewellery casting is an art form that goes back thousands of years. Since at least 1400 BC, artisans have been pouring molten gold into different moulds, using a technique so successful it’s barely changed from the moment mankind realised metal could be melted. After the gold solidifies, it’s carefully broken free of the mould and expertly sculpted into beautiful pieces of jewellery. The MATILDE artisan jewellers keep this tradition as beautifully sustainable as possible using 100% recycled gold.

STEP 4

Though we love to use traditional methods of production, technology has also allowed for these processes to be more dynamic than ever. We use 3D printing, detailed CAD designs and the lost wax process to heat the products to extreme temperatures to create our castings which will be filled with beautiful, molten recycled gold.

Fun Fact

Did you know that the process of lost wax casting, or investment casting, is still the most reliable and accurate means of reproducing intricate shapes in precious metals with the fine detail of an original pattern? The method actually dates back to the first civilisations in the Near East, and to a mix of early religion, art and metallurgy.